Combigrid® geogrids

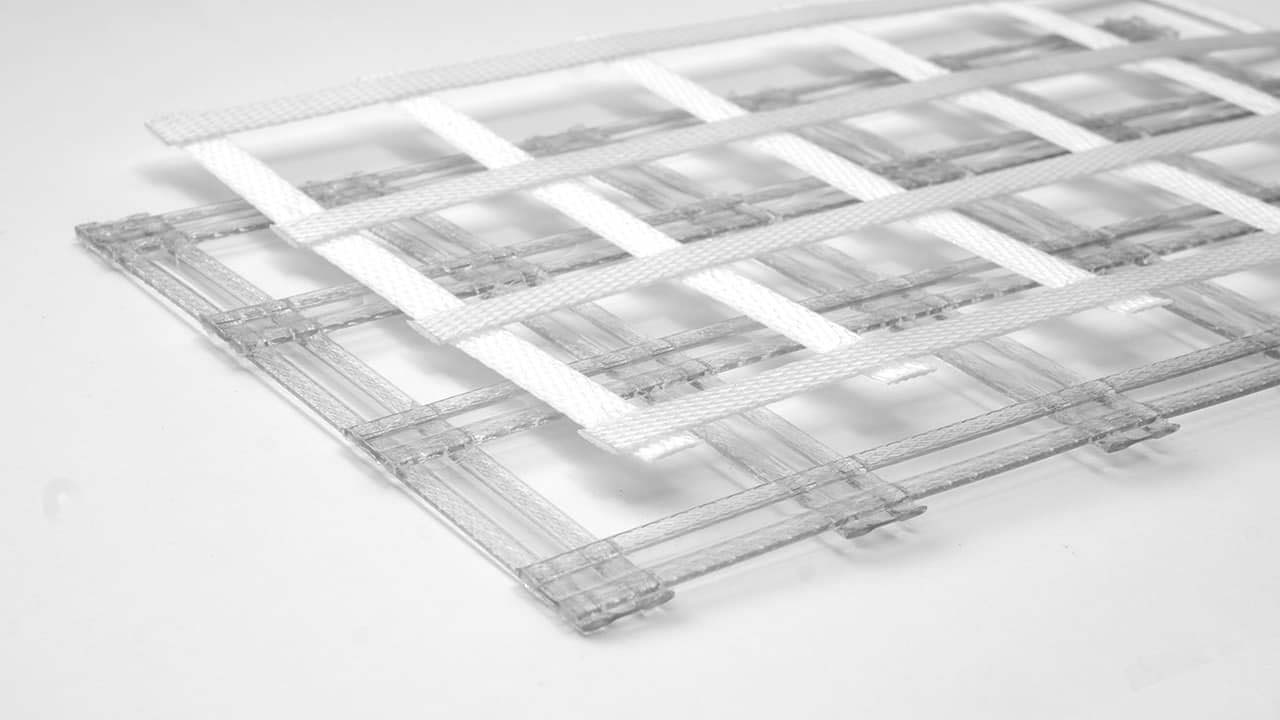

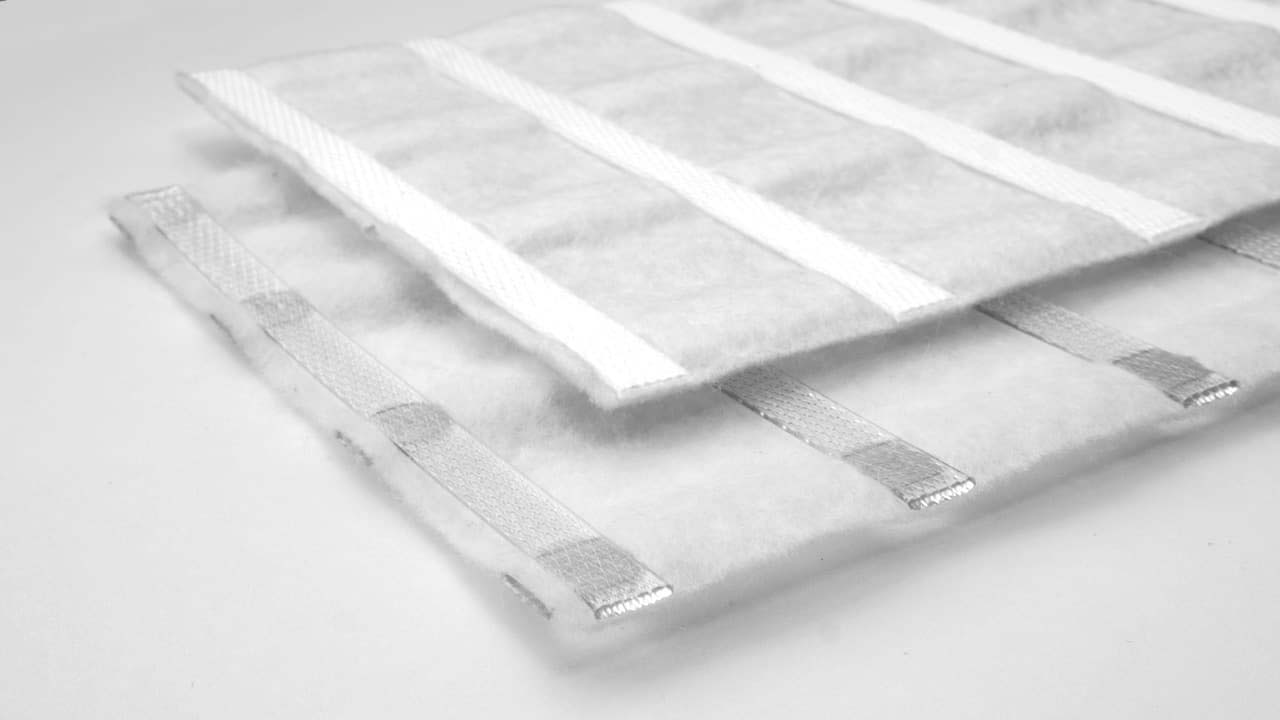

Combigrid® is a composite of a laid geogrid made of stretched, monolithic flat bars with welded junctions and a mechanically bonded and calendered filter geotextile welded within the geogrid structure. Combigrid® is used for stabilisation and reinforcement of soils in many fields of infrastructure, environmental protection, and hydraulic engineering applications.

Economic and safe – New paths for a sustainable infrastructure

Typical solutions with Combigrid®

Unpaved roads

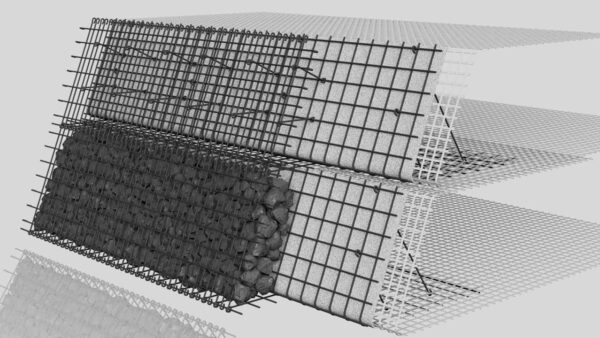

Unpaved low volume roads are extensively used for either temporary or permanent transportation purposes, such as haul roads, access roads or rural roads. Combigrid® is used at the interface between soft subgrade and subbase course to improve the bearing capacity and prevent migration of fines from the subgrade into the coarse aggregate layer.

Paved roads & storage yards

In paved roads or storage yard applications, Combigrid® is either used at the interface between soft subgrade and subbase or within the base or subbase course layer itself. This enables contractors to meet minimum compaction requirements and to reach the required bearing capacity for the overlying aggregate layers.

Railway construction

If the railway track is not capable to absorb the stresses from the railway traffic without causing detrimental deformations, maintenance or rehabilitation of the track is required. The geogrid component of Combigrid® reduces movement and particle reorientation within the sub-ballast and ballast layers. The geotextile component of Combigrid® prevents the subgrade from being pumped into the sub-ballast and ballast layer, thereby maintaining structural integrity of the track.

Working platforms

Working platforms are temporary geotechnical structures providing a stable working surface for piling rigs, mobile cranes, and other heavy construction equipment. Many working platforms are built on soft, compressible subgrades, providing inadequate support for the expected loads of the construction plant. Combigrid® can be used to stabilise and reinforce working platforms and to increase their strength and durability

Advantages of Combigrid®

Combigrid® is a geocomposite stabilisation and reinforcement solution. The unique manufacturing process produces structured, high strength, monolithic, pre-stressed polypropylene or polyester bars with a continuous molecular orientation. The extraordinary high extensional stiffness of Combigrid® efficiently reduces deformations in the subgrade which extends the service life of modern infrastructure.

Stress / Strain behaviour

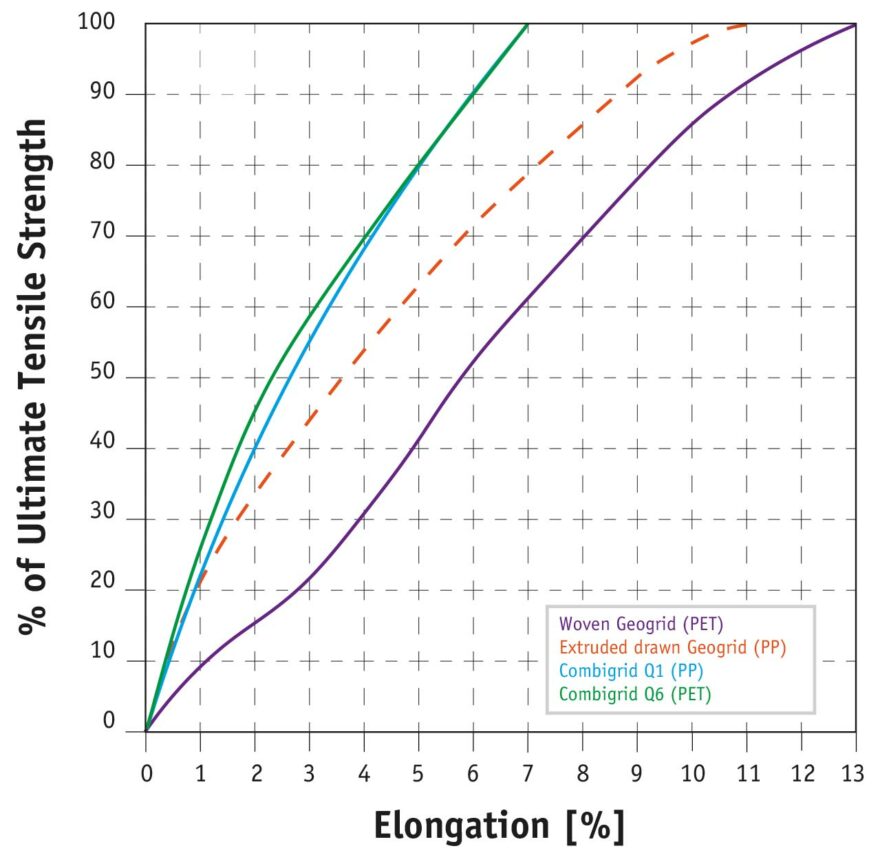

Geocomposites like Combigrid® are used wherever high strength is required at low elongation. The stress-strain behaviour (also known as tensile stiffness) of the geogrid is important when selecting, which type of geogrid is to be used. Geogrids will typically have a maximum elongation at break of 6% up to 15%, depending on the choice of polymer and manufacturing technology. However, the internal angle of friction of medium to densely compacted soils is reduced when the soil is subjected to axial strains of less than 2%. It is necessary to align the stress-strain behaviour of the installed geogrid with the strain behaviour of the soil. The performance of the geogrid at strain levels around 2% is therefore important and here Combigrid® shows its strength. Combigrid® provides excellent tensile strength properties at low elongations and demonstrates its advantages to hold the soil particles together at this important strain range.

Soil separation

The three-dimensional fibre matrix of the needle-punched Secutex® nonwoven, acts as separation layer between fine grained subgrade soil and coarse aggregate base course layers and ensures long-term filter stability. The properties of separation, filtration and reinforcement are combined in the product Combigrid®.

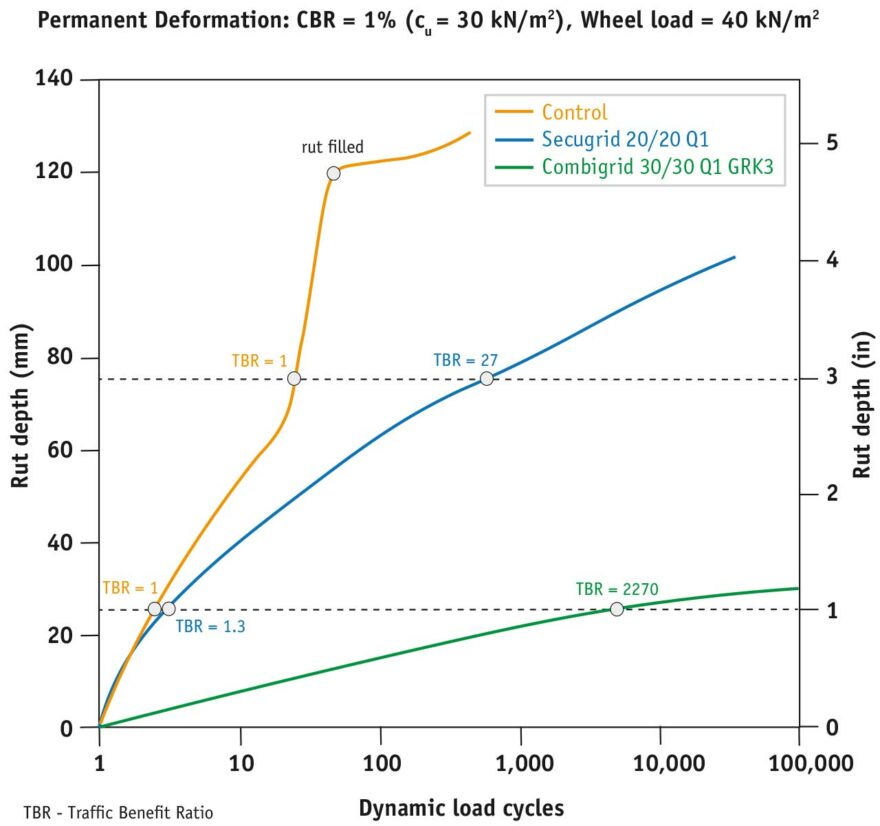

Tests to simulate the traffic passages on an unreinforced base course resulted in 3 inch (75mm) deep ruts after 20 load cycles, and it took 540 load cycles when Secugrid® 20/20 Q1 was used. However, when Combigrid® was used, the maximum rut depth of 3 inches was not reached even after 100,000 load cycles. Using a composite product made of a geogrid and a needle-punched nonwoven firmly bonded between the longitudinal and cross bars at the interface between soft subgrade and base course layer worked really well. Combigrid® – not just a geogrid. THE solution for infrastructure projects on low bearing capacity subsoil.

Stress-strain curves of different geogrids. Scaled up detail illustrates typical working strain levels (≤ 2% elongation).

Combigrid® and Secugrid® traffic benefit ratio (TBR) over a very weak subsoil, compared to an unreinforced section (for subsoils CBR 1%, for details see EuroGeo4, paper 229).

More geogrids

Secugrid® geogrids for soil stabilisation and reinforcement. Secugrid® is a structurally sound and stable geogrid for soil reinforcement, manufactured of extruded and drawn polypropylene (PP) bars, laid and welded solid together.

Secugrid® HS combines high tensile strength and low creep tendency with extreme robustness and resistance.

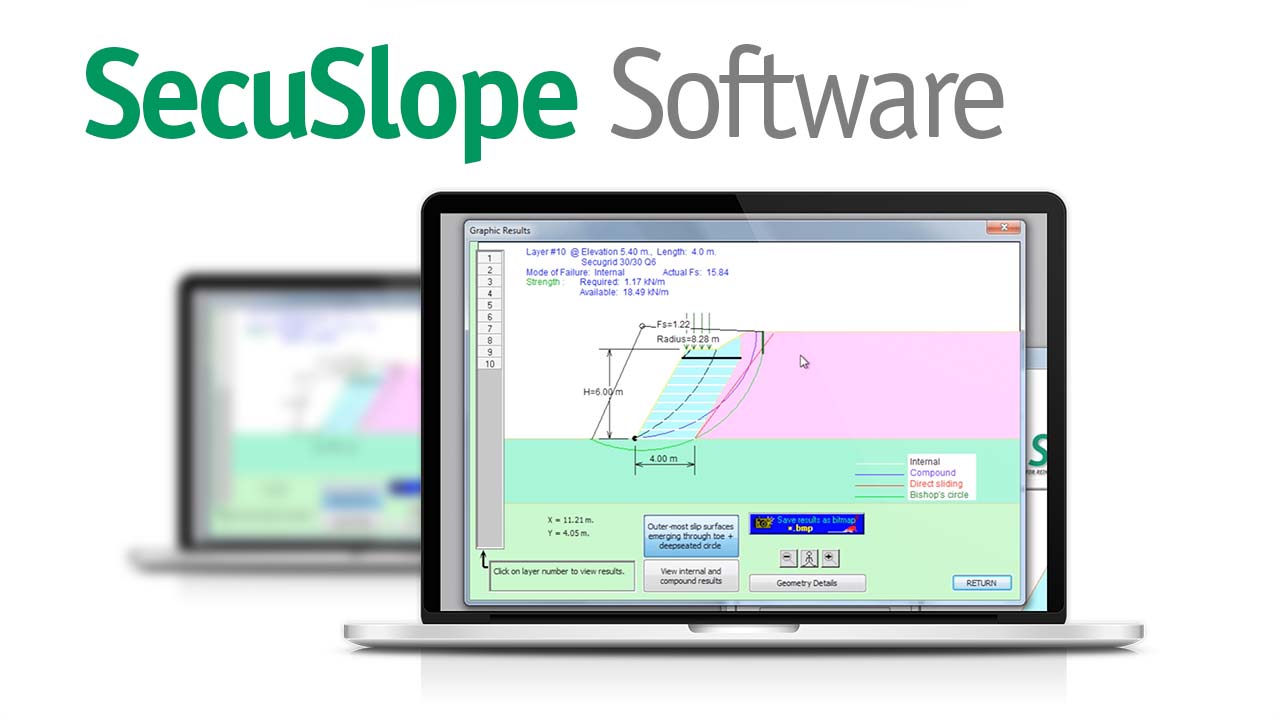

Geogrid software

SecuSlope 3.0 is a user-friendly, interactiv, design-orientated program for creating geogrid-reinforced slopes, walls, and abutments.

With the Naue Platform Software, you can design base course thicknesses for Secugrid® or Combigrid® stabilised and reinforced base courses in different applications such as working platforms for tracked plants (e.g. piling rigs), hardstands for cranes and heavy equipment, storage areas, etc.

With the Naue SecuCalc Software, you are designing base course thicknesses for Secugrid® or Combigrid® stabilised and reinforced base courses in road construction as well as for parking and storage areas or similar applications.