Innovative dyke construction solutions with geosynthetics

The roles and advantages of geosynthetics in modern dyke designs are many. Bentofix® geosynthetic clay liners (GCLs) are used as waterside sealing systems for dyke slopes and forelands. This geosynthetic barrier solution provides a cost-effective, durable alternative to conventional mineral seals (e.g., compacted clay). Filter geotextiles such as Secutex® H and Secutex® increase the working life of the drainage layer and prevent piping below dykes. Geogrids increase a dyke’s external stability and reinforce affiliated road bases. These solutions also reduce the potential impact of differential settlement in a dyke body. Furthermore, the construction and load-transfer efficiency of geogrid reinforcement enables slopes and walls to be constructed on the water or landside of a dyke with a minimal construction footprint, making reinforcement ideal for sites with limited space.

All of these geosynthetics – GCLs, geotextiles, geogrids – provide proven, site-adaptable technical solutions. And, as geosynthetic design and specification is rooted in repeatable data, documentation is readily available for all products to ensure they meet or exceed a project’s minimum technical requirements.

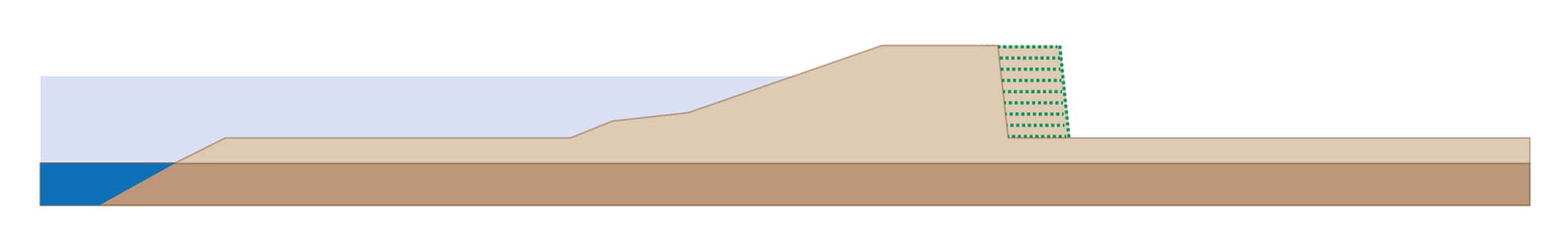

Advantages of geosynthetic clay liner solutions in dykes

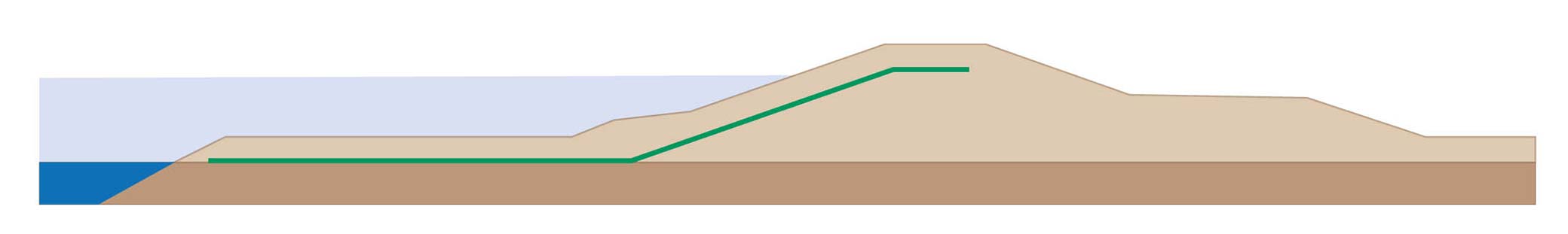

Filter geotextile for dyke drainage core

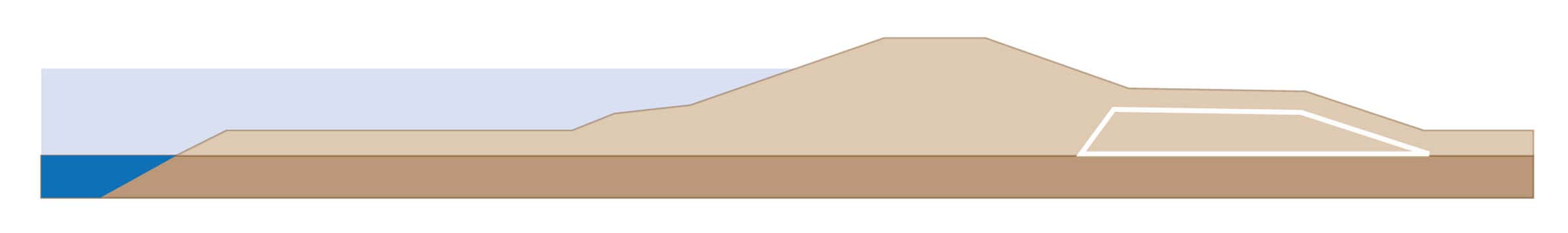

Geogrids & composites for construction over soft subsoils and roadway reinforcement

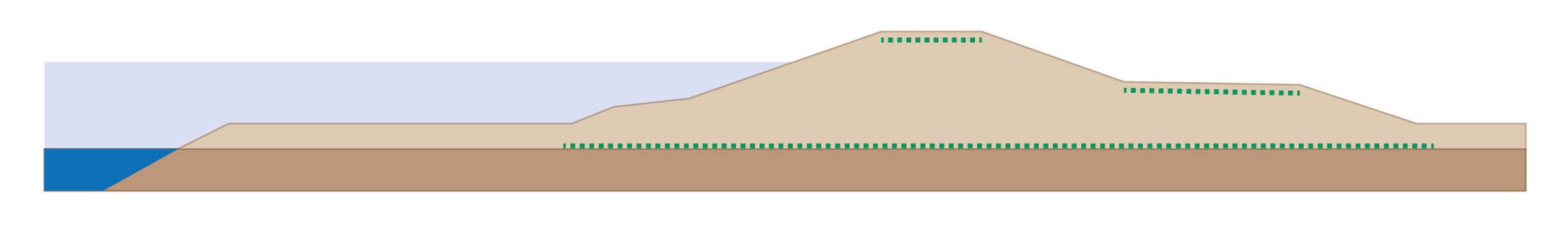

Geosynthetics for dyke retaining walls